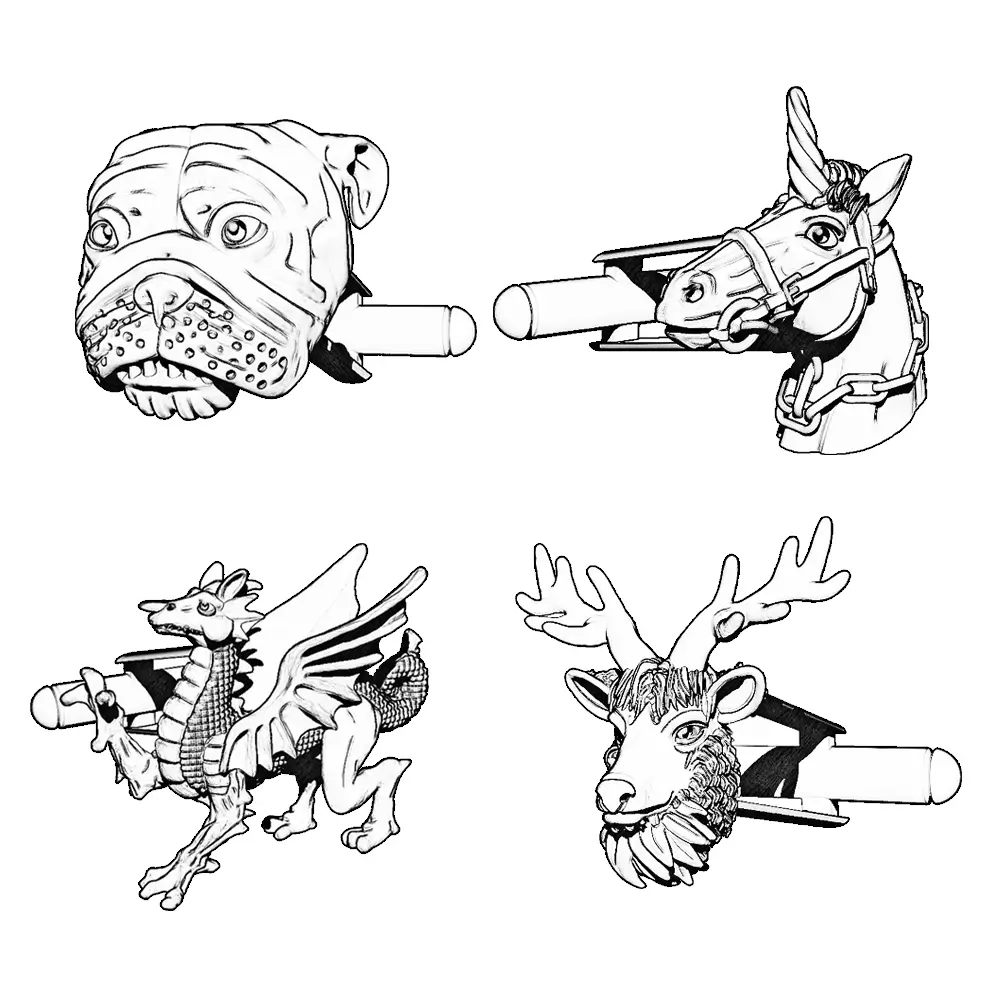

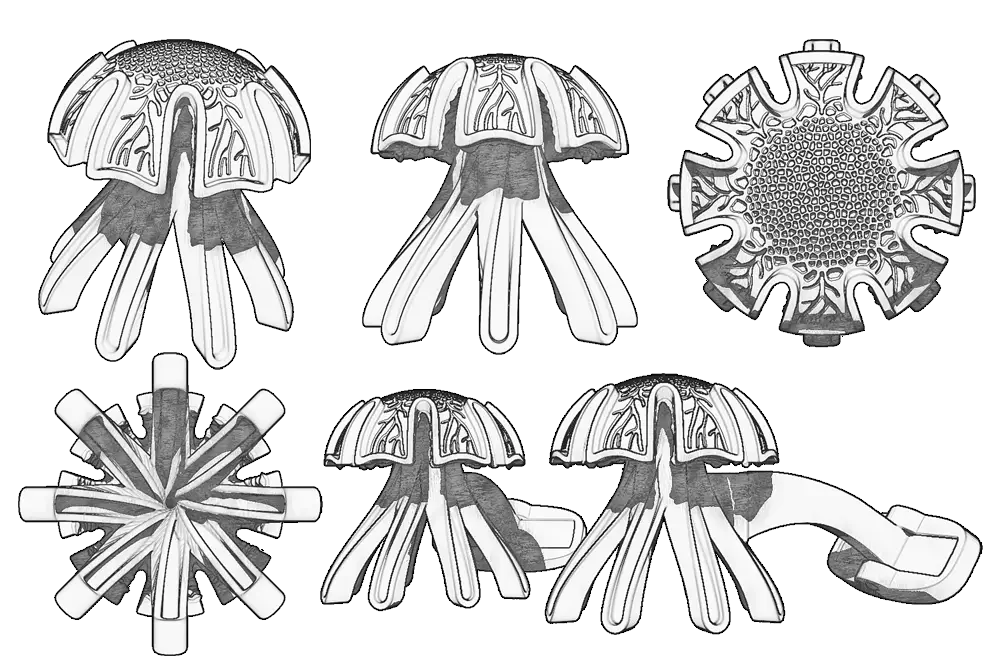

We can make just one pair—or hundreds. Smaller runs cost more, since setup is spread over fewer units. But if it matters, we’ll make it happen.

Usually around 6 weeks. Got a tight deadline? Let us know—we’ll see what’s possible.

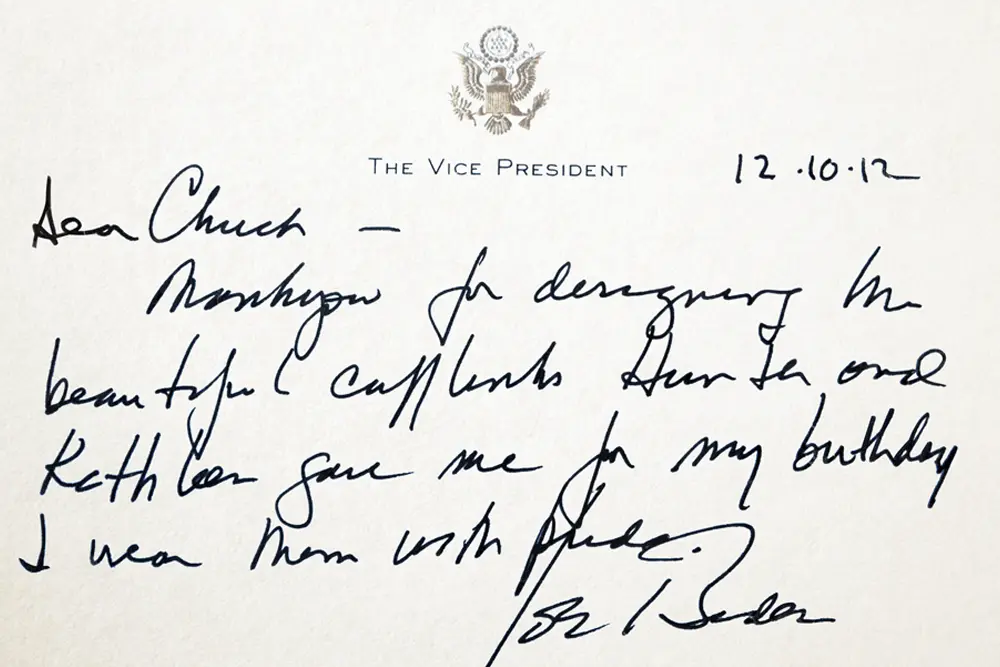

Of course. We’ve got stock options ready to go—just send us your engraving and we’ll handle the rest.

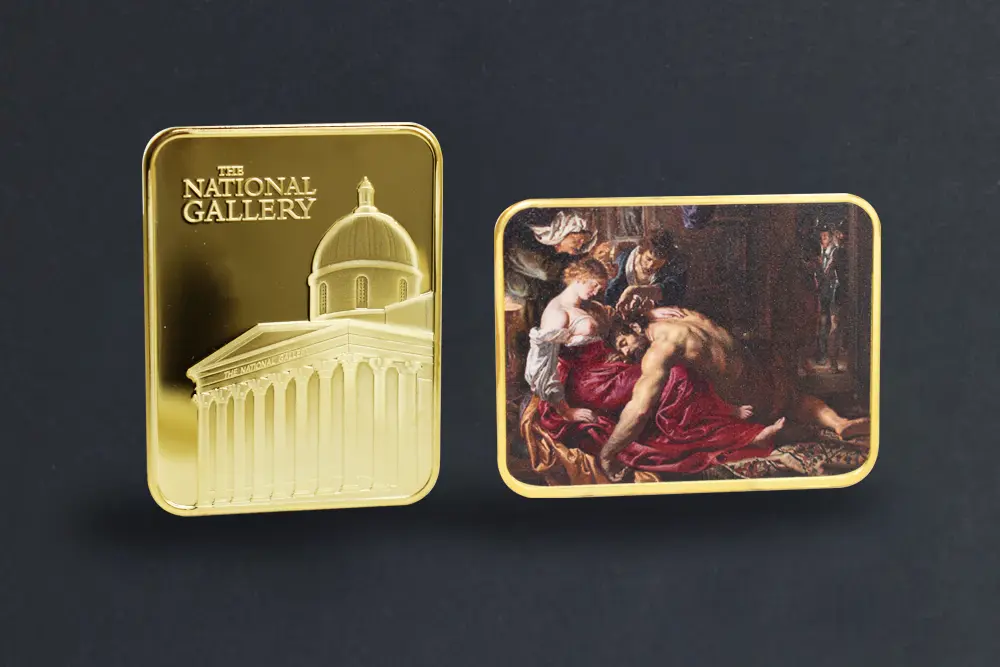

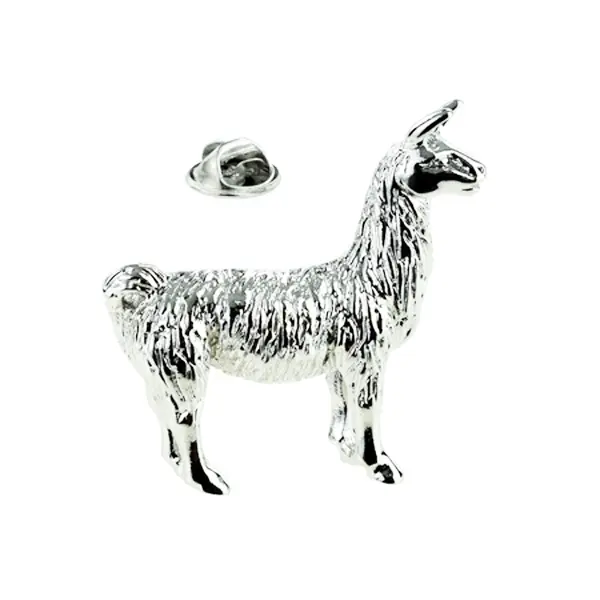

We do. From solid sterling silver and hallmarked gold to silver or gold-plated finishes—whatever fits your project brief and budget.

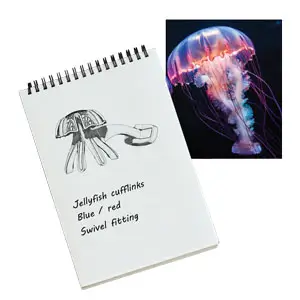

Yes. We offer printed cufflinks, which allow for detailed designs at a more accessible price point.

Yes. Whether it’s a one-off gift or a full wedding party, we’ve got you covered.

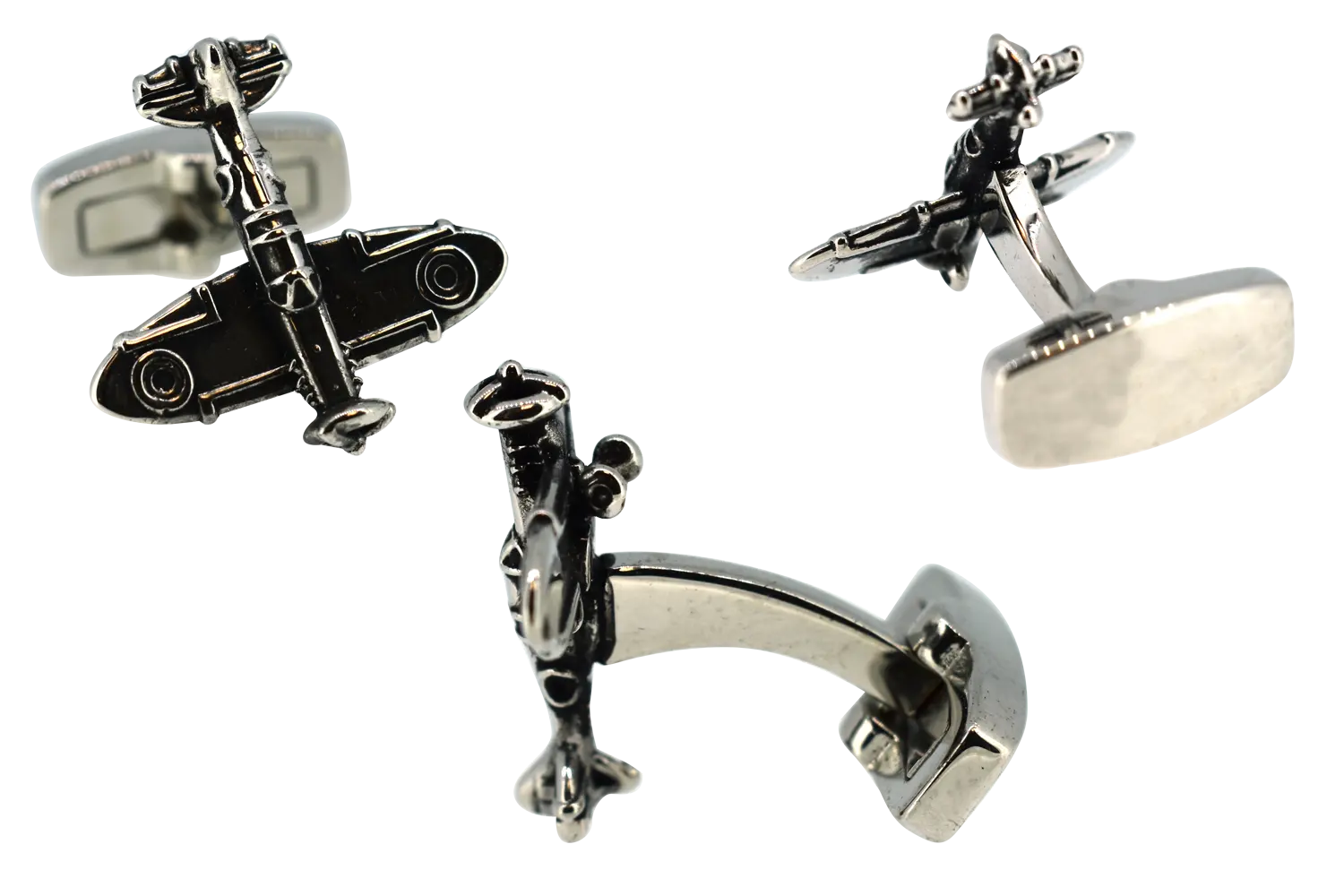

They’re small, functional accessories that hold your shirt cuffs together. But really, they’re a way to add personality to a suit. Formal, personal, or somewhere in between.

Merit Badge & Regalia Co Ltd, 4 George Baylis Road, Droitwich, WR9 9RB, United Kingdom

+44 (0)1905 791350 | sales@meritbadge.co.uk