Ordering custom badges and medals can accumulate cost quickly. Design, minting, labour and enamelling all carry their own costs. Reducing cost through cheaper alternatives is typical practice but the cheaper alternatives rarely have any pro’s apart from being cheaper.

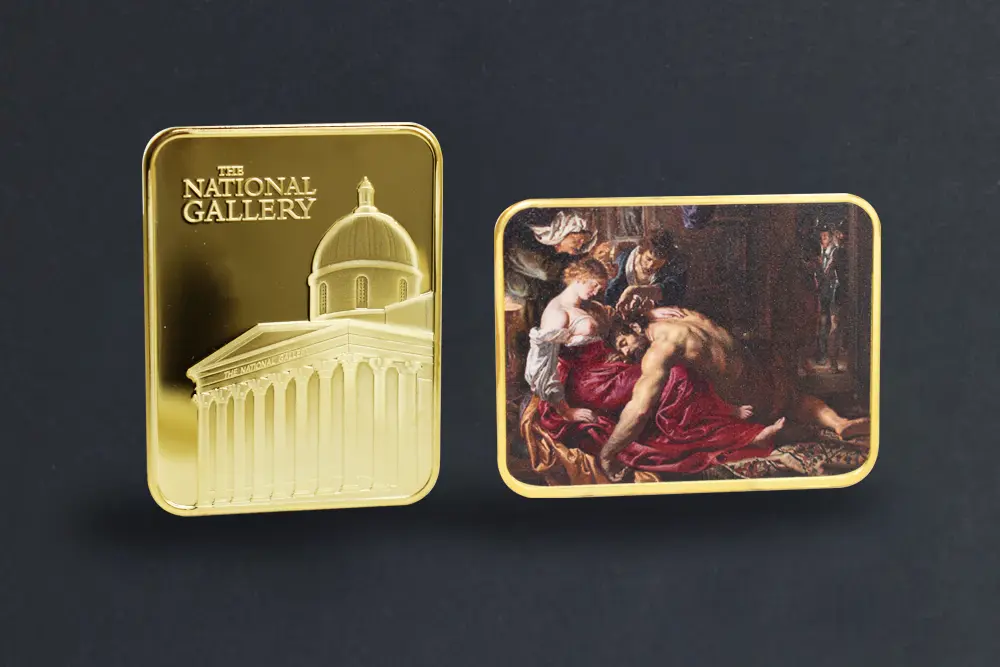

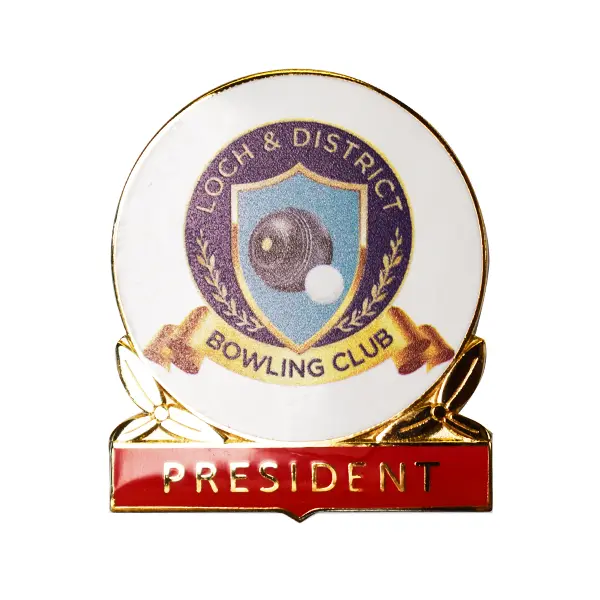

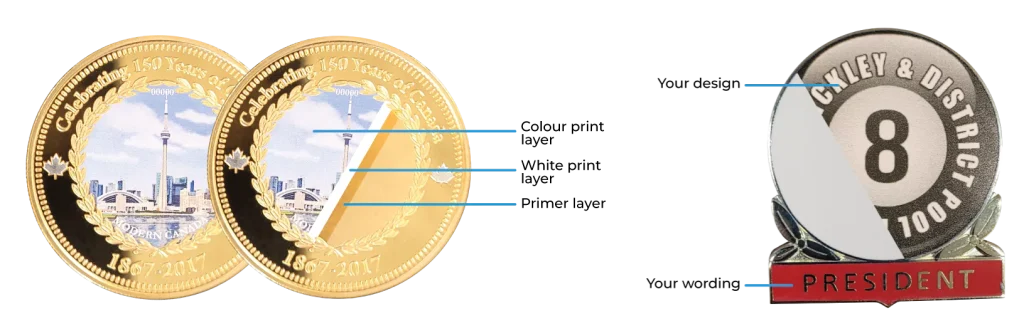

While some charges may be inescapable, printing custom artwork directly to the badge or medal is a sure alternative to the norm. This method avoids the enamelling cost by exchanging it for our eco-UV ink. Utilizing print in replacement to the conventional method opens the door to new possibilities in design allowing for detailed artwork and a diverse colour palette. If the decision is to go with our generic stocked options, you will also avoid the minting start-up die casting charge as the die has already made.

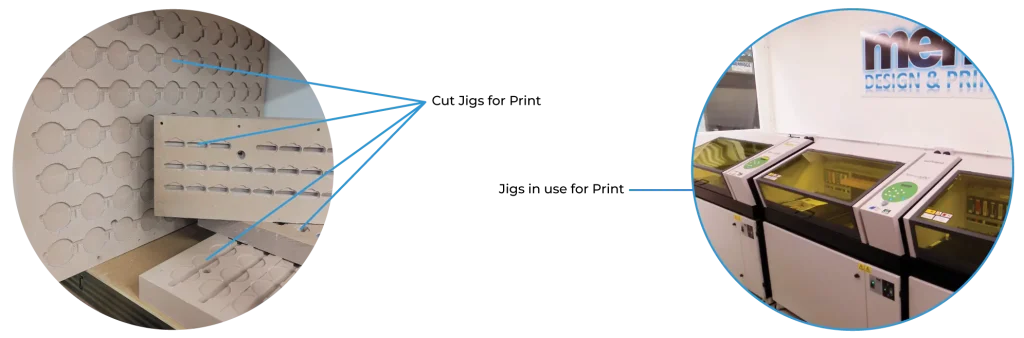

Cutting precise jigs using the in-house CNC machine to escalate production allowing for multiple prints off the same run on our digital UV printer. This reduces the labour cost significantly and reduces the turnaround time on production therefore delivering the finished product sooner. With the artwork setup and the jigs cut repeated orders are easily produced identically to the first order.

Cheap and regularly ordered products for events, such as medals for school awards or badges for students, are ideal when utilising print, but print is not limited to cheap products only as it reduces cost. Print significantly increases a products appeal with its ability to extend past the conventional constraints with its precision and diverse colour range.

Utilizing print is a great way to reduce the overall cost of your order while maintaining high quality expectations. By reducing production time and expanding the creative options available to you while not just maintaining the cost but reducing it, it is a no brainer!

Merit Badge & Regalia Co Ltd, 4 George Baylis Road, Droitwich, WR9 9RB, United Kingdom

+44 (0)1905 791350 | sales@meritbadge.co.uk