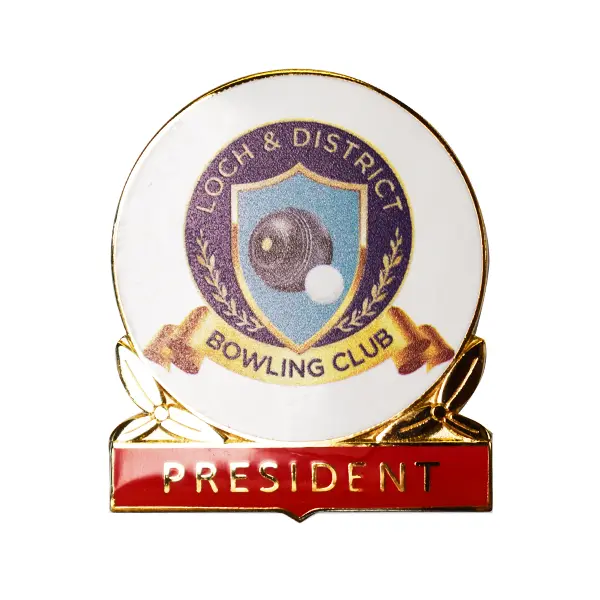

We were contacted by the client to design and manufacture a custom badge based on their organisation logo. Initially we drew up a design based on sizes from an existing badge that the client felt would work. Due to the intricacies of the organisation logo we had to simplify aspects to ensure that these parts would be capable of holding enamel sufficiently. We made some preliminary sketches of the design and when satisfied with its feasibility converted these sketches to vectors in a 2D CAD program.

Two-Dimensional Computer Aided Design (2D CAD) serves as a pivotal tool as it offers a flexible platform for generating vectors compatible with other software programs, facilitating quicker rendering and ultimately die manufacturing. It also enables accurate measurements to be taken to ensure that any metal parts in the badge are robust enough to survive the die stamping process and any channels are large enough to hold enamel evenly. Having drawn up these vectors we were able to import them into a 3D CAD program to produce a 3-dimensional CAD model relatively quickly. This model was then rendered to give the client a better understanding of the plating finishes available, as well as the enamel pantones chosen.

This badge design was presented to the client and although popular, it was decided a smaller scale badge might be preferable to reduce costs. The desired badge size was reduced to 20mm and this now created issues in terms of the feasibility of fitting enamel into the design. To retain the integrity of the overall logo design rather than differentiating the separate parts with different coloured enamels, the badge was re-sketched with different logo aspects at different heights and different textures.

The vector file was updated with the badge amendments and new render files were produced to display the final visualised product. Once these designs were approved, we were able to set about the process of manufacturing dies to enable the badges to be stamped on high tonnage knuckle presses ensuring high quality finish and consistency.

The final product was manufactured in two different enamel pantones and was enthusiastically received by the client. In summary the project emphasised Merit’s ability to collaborate closely with the customer to turn their ideas into fully formed badge products. The resulting badge helped to promote the client’s organisation. This case study demonstrates our expertise in custom badge design and manufacturing, showcasing our ability to overcome design challenges and deliver high-quality products. If you are looking to create similar products to enhance your company or organisation’s visibility, please contact us. We are ready to help bring your ideas to life.

Merit Badge & Regalia Co Ltd, 4 George Baylis Road, Droitwich, WR9 9RB, United Kingdom

+44 (0)1905 791350 | sales@meritbadge.co.uk