Nope. We can produce a single piece or thousands. Once the die is made, every coin comes out clean and consistent.

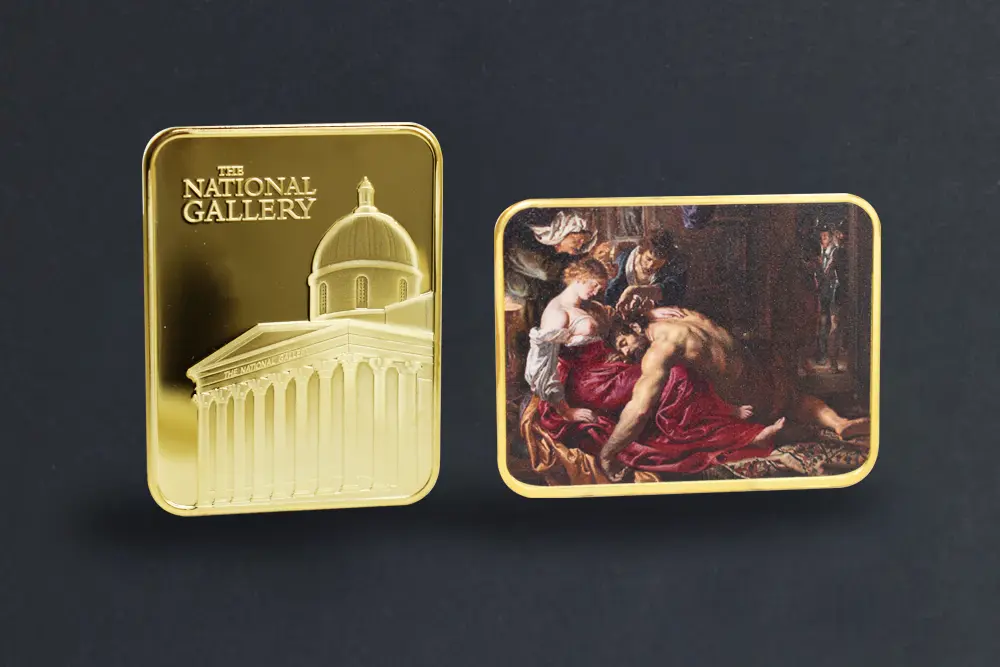

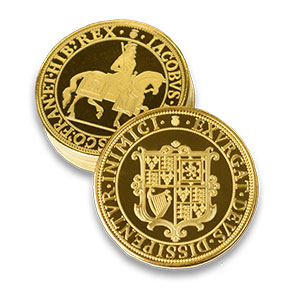

Yes—we can strike in solid gold or sterling silver or use brass with high-quality plating for a more affordable option.

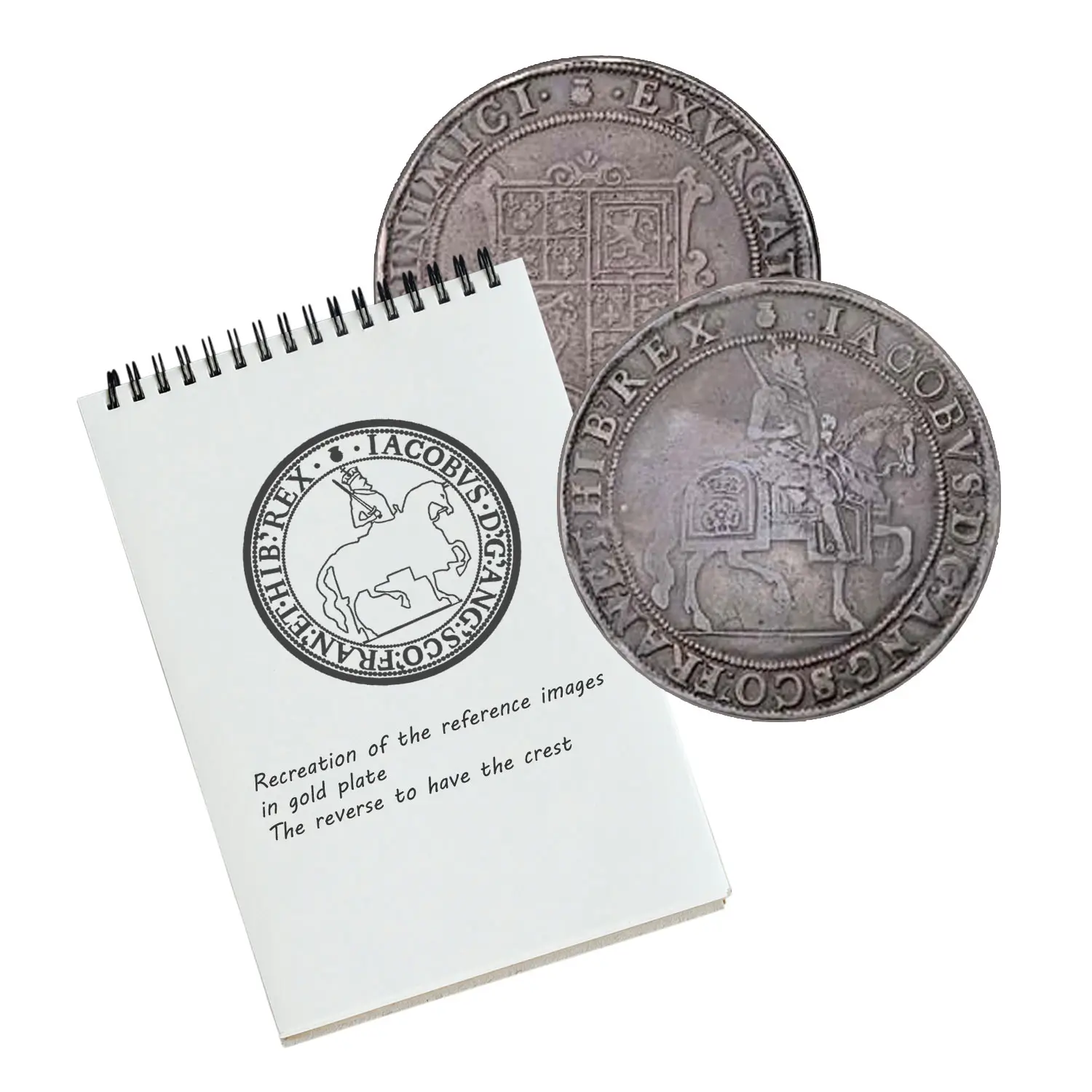

A die is a custom steel tool we use to strike your design into metal. It’s what shapes each coin or medal with precision and repeatability.

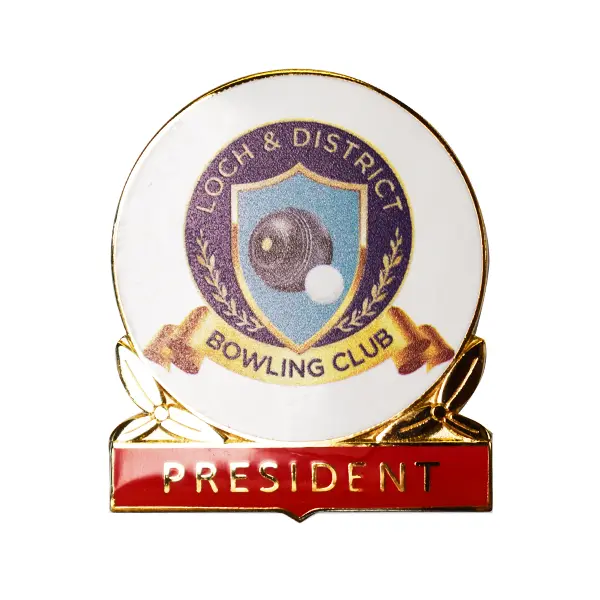

Absolutely. Send us a design—or even just a rough idea—and we’ll handle the rest. Size, finish, shape—we can adapt it to fit.

Yes! As the die has already been made subsequent orders will not have a die charge. Cost of materials may fluctuate.

Yes. We make both medals and coins for events. Engraving, full-colour print, or enamel can help your design stand out.

Definitely. We offer a range—from cast medals to struck coinage—at different price points. Tell us what you need, and we’ll guide you to the best fit.

Merit Badge & Regalia Co Ltd, 4 George Baylis Road, Droitwich, WR9 9RB, United Kingdom

+44 (0)1905 791350 | sales@meritbadge.co.uk