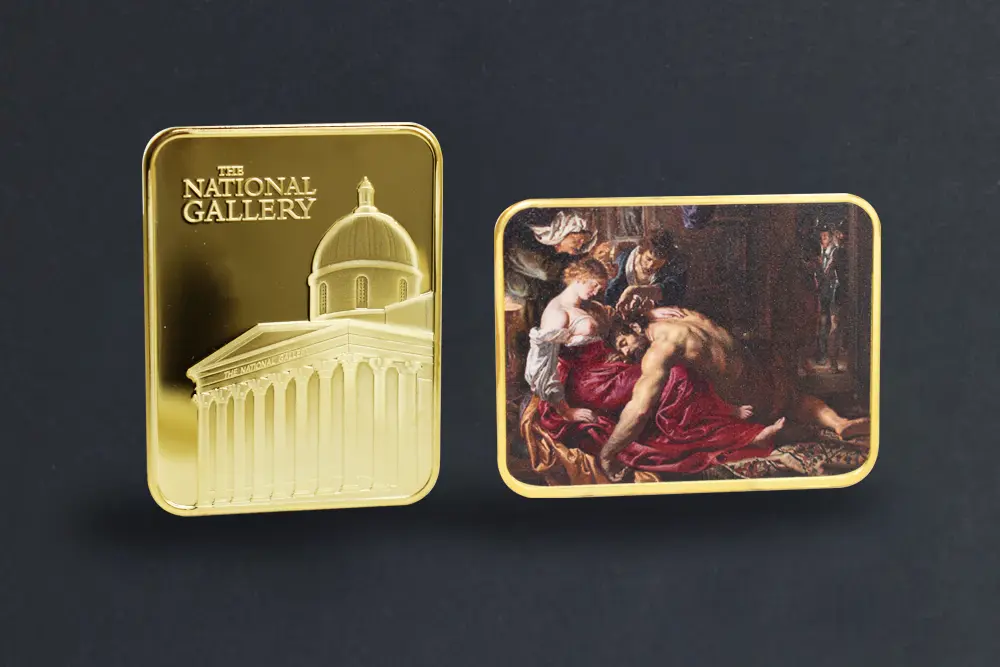

In 2022 the film Casablanca reached the milestone of its 70th anniversary since its original release. Keen to highlight this milestone and pay homage to other films from this golden age of cinema, our client had secured permission from the copyright holders to commission a series of collectible printed ingots featuring original movie poster artwork. Our brief was to design these ingots under the working title of “History of Film.”

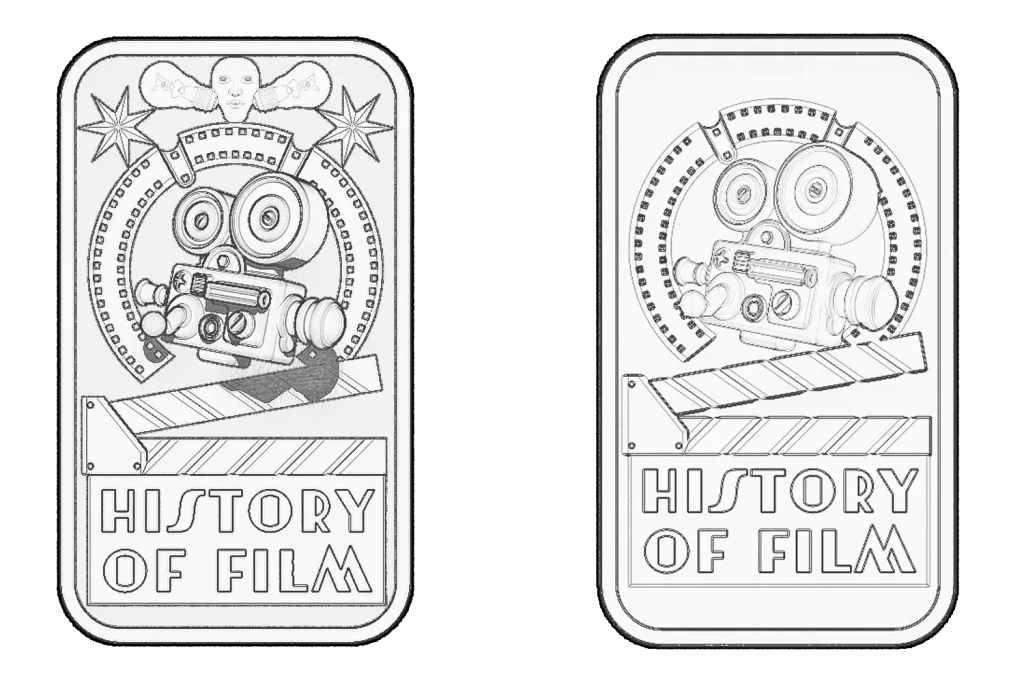

We decided to make the printed movie poster on the reverse of the ingot, as bold and eye catching as possible. To maximise the size of the print available we agreed to cut a blank die featuring only a rim to hold the print. The die surface was matted to provide a better adhesive surface for the print. The obverse of the ingot needed to best represent the collection theme of “History of Film.” We began initial sketching to try and incorporate themes associated with vintage films into an ingot design. A clapboard with a vintage film camera and celluloid film was surrounded by stars, dressing room vanity lights and the traditional theatre mask, before being simplified back to just the clapboard, vintage camera and celluloid film arch.

With a design in mind, we turned to CAD software to create a 2.5-dimension relief of the chosen proposal. We were able to render the design in different material finishes to present different options to the client. The design was approved as a base metal ingot with a gold-plated finish.

The next step was to take the 2.5D CAD model and run it through CNC software to create a cutting guide for the CNC machines to follow and cut a die. At this stage we were also able to analyse the model in terms of the height of the relief to ensure that the details would be visible on the final stamping and that the die cut would be robust enough to survive multiple stamping runs, with no weak points.

A die was cut using CNC manufacture and set up on our high tonnage knucklepress machines, housed in our onsite stamping facility. Meanwhile ingot blanks were carefully polished using a combination of vibro-polishing machines and traditional hand polishing skills. A skilled technician determined the optimum settings in terms of stamping tonnage and stroke repetition to produce near-proof quality, sharp ingots. The stamped ingots were now ready for print and transferred to our knowledgeable print team. To ensure the highest print standards our print technicians use jigs specifically designed to hold the coin or ingot to be printed. This enables the print registration to be lined up quickly and efficiently and is conducive to large print runs with repetitive accuracy. We use eco-friendly, UV inks that comply with stringent testing for low volatile organic compound (VOC) emissions. The technicians in our onsite print facility have over ten years of experience using digital UV printers and have developed methods to ensure durability and quality when printing to metal substrates like coins and ingots. The movie poster artwork supplied by the client was successfully printed to the reverse of each ingot.

In conclusion the client was delighted with the efficiency of the project and the final ingot product. They are currently negotiating distribution options with various marketing agencies. Internally, this project shows how all the departments at Merit work together to create high quality coins and ingots that resonate with collectors and befit the status of a commemorative token. From initial idea, through the design stage, to the cutting of dies and the stamping of the product and onto the final embellishment with print, we provide a complete service to design, mint and print. Contact us to discuss your next project today.

Merit Badge & Regalia Co Ltd, 4 George Baylis Road, Droitwich, WR9 9RB, United Kingdom

+44 (0)1905 791350 | sales@meritbadge.co.uk