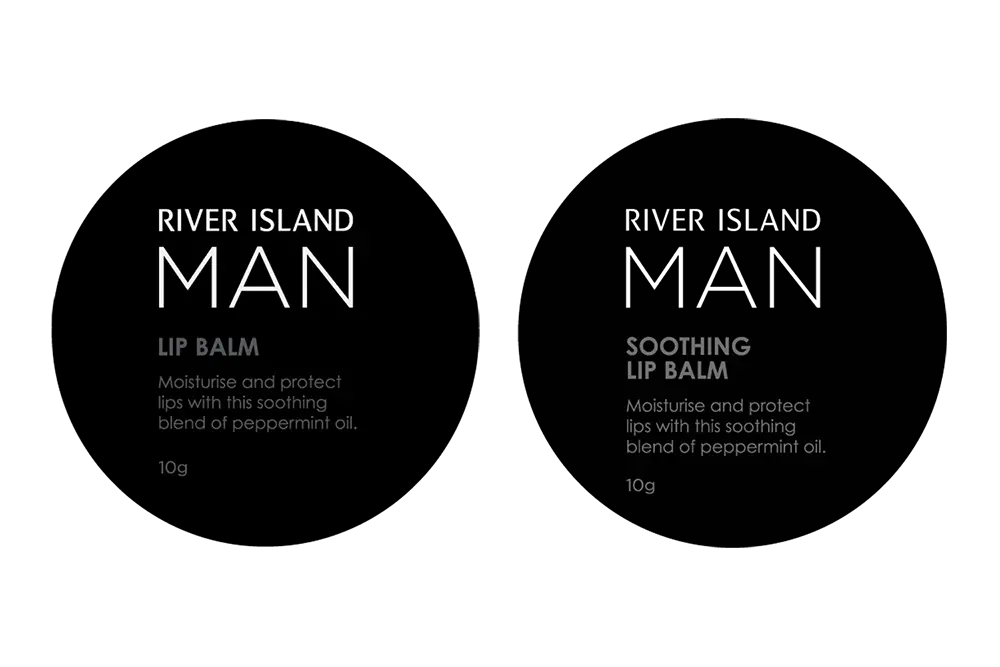

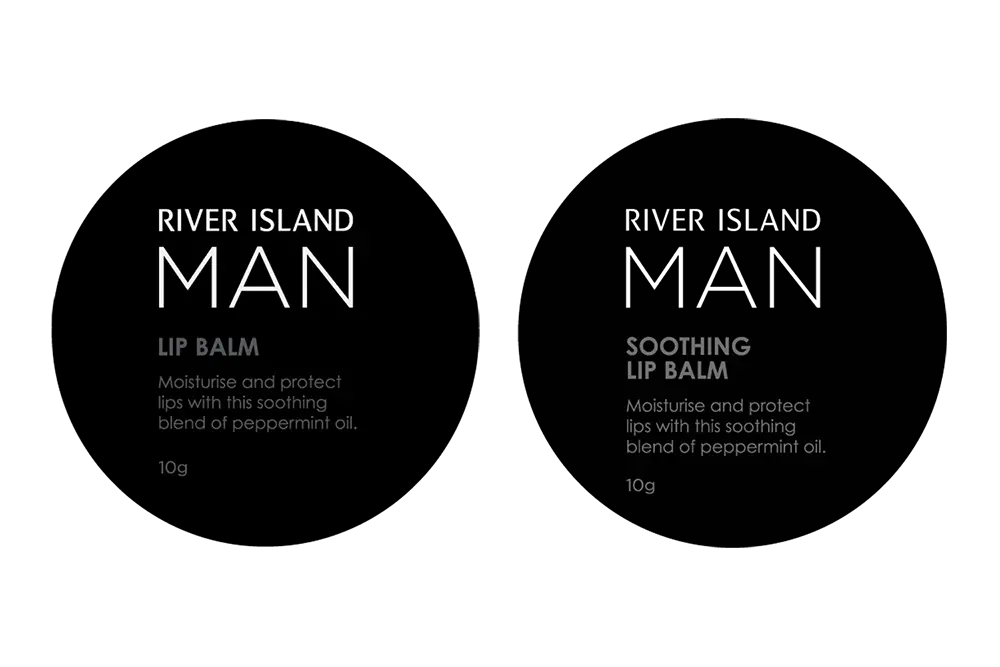

We were approached by a client with a unique, business to business printing job which had encountered specific problems. The job involved printing Aluminium tin lids with the appropriate manufacturing branding and product information. Usually, the client would have gone about the task by cello-wrapping or shrink sleeving a plastic wrapper to the tin lids, however due to the size, materials and the need to reduce excess packaging waste this approach was deemed unsuitable. The cello wrapping labels were failing to bond with the aluminium tin lids and peeling and due to the nature of the product, a lip balm, the client didn’t want to possibly contaminate the balm by adding adhesives to keep the labels in place.

Using the cutting edge, UV digital printing technology located in our on-site print facility, we were able to experiment with a range of print coatings to produce a durable print layer which bonded directly to the product tin lids. Not only did this solve the problem of labels peeling, but by printing with eco- UV inks we reduced the possibility of contamination to the lip balm product, as these inks are certified to ensure they comply with stringent and extensive standards for low volatile organic compound (VOC) emissions. This certification guarantees that our printing process adheres to high environmental safety norms.

Having found a solution and received the approval of the client for this printing method, we were able to design a series of jigs to hold multiple tins, enabling high-capacity print runs. We machined these jigs using the precision engineered tooling of our on-site CNC machinery to fit our printers. Our skilled and experienced print team set about creating print files to ensure maximum print quality and precision. Ultimately, the tin lids were printed to the required specifications well in time for the product launch.

Merit Badge & Regalia Co Ltd, 4 George Baylis Road, Droitwich, WR9 9RB, United Kingdom

+44 (0)1905 791350 | sales@meritbadge.co.uk