Have you ever held a piece of history in your hand? This article explores how we use our skills to create contemporary recreations of historical coin designs to allow you to do just that. We explore the process of recreating replica coins that perfectly reflect their spirit and show you how we can help create your own custom collectable coins.

Researching the Past

Coins from Ancient times up to the early Modern period can still be a rare opportunity to take you back in time. Coins were minted not so much for currency but to express the ruler’s key message and promote their rule.

The process of minting a replica coin begins with research and finding reference material to ensure that the design is as close to the original as possible. This foundation is the knowledge that will guide our efforts to recreate the coin with authenticity and accuracy.

Detailed images from the pre-modern period can be difficult to find. Even some of the finest examples are worn and show their age. With some examples, it can be difficult to establish what the letters read, as this is one of the details that can be worn down over the years. In addition to the age of the coins, the fact that the original dies would have been cut by hand means you can see differences in each example image. The letters in particular take a different form depending on the coin. In general, we take a middle path and take our best-informed guess.

If you have a coin or medal that you would like us to make, we can bring this wealth of design know-how to your project, so get in touch.

From History to Design

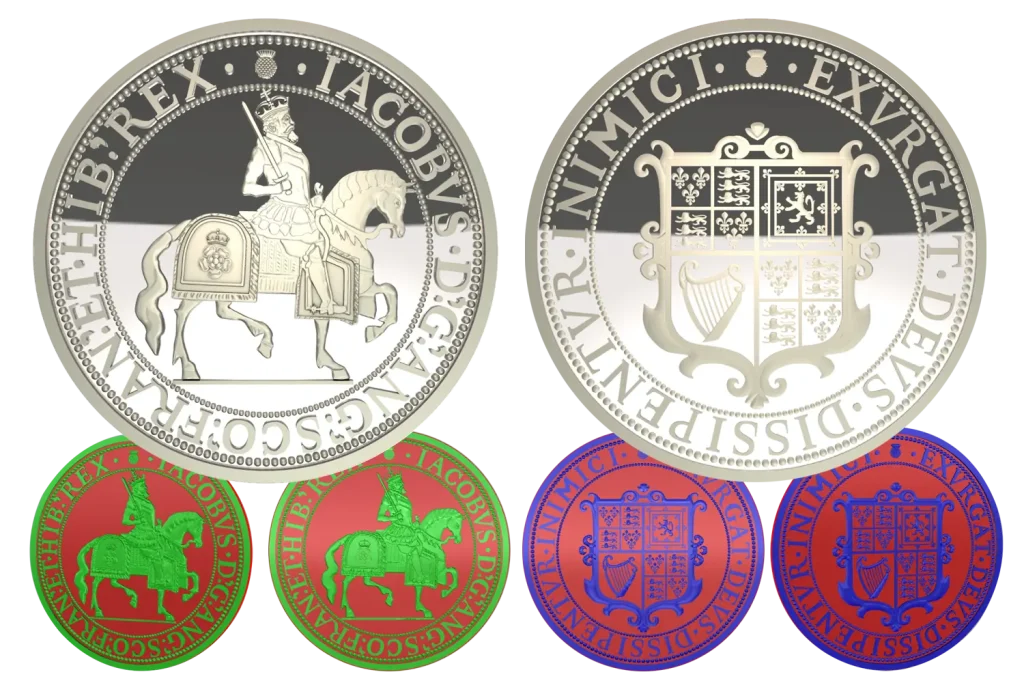

The example that we will focus on here is the King James I replica Coin. He was the ruler who united England and Scotland and was the first of the line of Stewarts.

We start with CAD software which is used to draw vector lines around the elements using the reference materials. To recreate this coin we started with the modelling of a detailed relief, we created an alpha and then used it in a 3D sculpting CAD program. As above we are mindful of the details at this stage so they will be captured in the final piece. Details of the emblems and figures are digitally sculpted while trying to add modern levels of fine detail.

The completed 3D model can also be used to create high-quality renders. This in the early stages can help the client to understand exactly what the finished product will look like. In the later stages, these models can be used to form artwork for sales material or videos that can be used in advertising.

The 3D relief is the digital model that allows modern die-sinking machinery to cut dies. The dies are high-quality tooling steel that once cut has to be hardened. This completes the die and, once dressed, it is ready for minting the coins. In the case of the King James I replica coin we selected a shiny table and matt details.

After you have invested in the creation of these dies you can keep seeing the rewards long afterwards. If you would like to see more about our design process click here!

Bringing Designs to Life

Once the dies for both the obverse side and the reverse side are completed, then each stamping should reflect the quality that is set into the die. To ensure premium copies, the coin is struck from a coining quality blank. This happens in-house in our UK production facility.

The blanks are prepared before minting, and the chosen size of the blank undergoes a series of polishing techniques. We keep various standard sizes of blank in stock including 32mm, 38.6mm (crown size,) 44mm and 50mm.

We can select a variety of materials and finishes. We can mint the coins in 9ct gold or Sterling silver. We can also mint in a base metal and finish in a gold or silver plating layer.

For the King James I replica Coin in the image we used a gold plate on bass metal, this gives a strong result and contrasts the matt and shiny table. This could be said to be a near-proof finish.

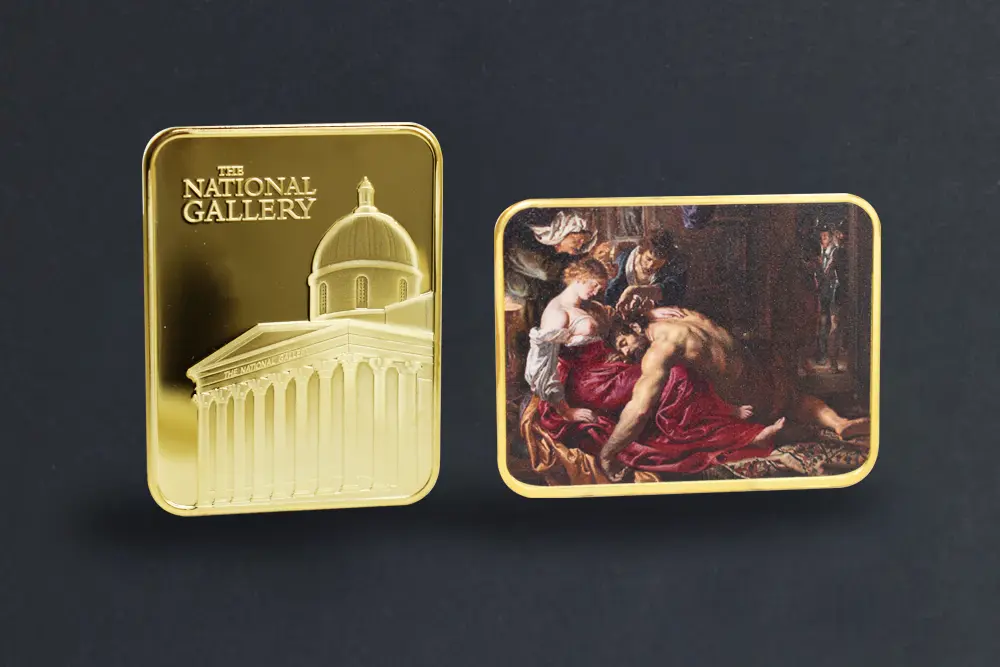

In adding finishing touches it is important to remember that we have other finishes we offer for use on coins and medals. These can include an antique silver effect or antique brass. We could also add a paint wash, antique effect lacquer or full-colour print.

To enhance the final product these replica coins, which are meant for the collector market, would normally be packaged in a capsule. The coin capsule helps to keep the coin in mint condition. Post-sale customer engagement with the coin includes an information pamphlet to describe the coins’ interesting points of interest and in this case the details of the history of the coin. This kind of content adds value, improves the customer experience, and encourages continued interaction with the consumer beyond the sale.

If you want to see more examples of the finishes available *click here*

Creating Your Masterpieces

This example of a custom coin design for the collector’s market allows for creativity while preserving historical integrity. Work with our design team to incorporate your unique elements that reflect your vision, making each coin a unique collectable.

As you will (hopefully) agree, we have demonstrated that we can employ a blend of traditional die stamping and modern print techniques to achieve a great quality in commemorative coins. Each project is crafted, starting with carefully prepared art, which helps to create the dies. This is followed with preparation of blanks, ensuring the highest quality of relief on the coins.

We can also help guide you through any packaging that you may require. From simple pouches to full custom boxes.

Get in touch to see if we can help with your concept or project. We’d love to hear your ideas.

In Conclusion

Recreating historical coins as modern replicas is not just about preserving history; it’s about creating a tangible connection to the past. Whether you’re selling to a collector market or a group of history enthusiasts, designing custom coins is a rewarding undertaking that combines craftsmanship, and historical appreciation. Once the investment is made in a die you can reap the rewards again and again.

Ready to create your own piece of history? Contact us to start your custom coin project today.

FAQ:

What is the process for obtaining a quote for a custom replica coin project?

Contact us and talk to our friendly team. We can help guide you through the process, give you a guide on the timescales, and quote costs depending upon what you require.

Are these fake coins ?

The example above is for replica coins for the general interest and the collectors market. They are not a copy or counterfeit. They would be marked as ‘copy’. The size, finish and material details are also different from the original to differentiate them and to avoid confusion.

Merit Badge & Regalia Co Ltd, 4 George Baylis Road, Droitwich, WR9 9RB, United Kingdom

+44 (0)1905 791350 | sales@meritbadge.co.uk